In order to continuously strengthen the intrinsic safety level of enterprises, in 2025, Harnas New Energy Group, based on the new situation of work safety, has taken "implementing responsibilities, pre-controlling risks, and enhancing capabilities" as the main line and fully launched the annual work safety campaign. In the first quarter, through special actions such as establishing a three-level responsibility transmission mechanism, innovating an internal and external collaborative training system, implementing penetrative hidden danger investigation, strengthening double rechecks for high-risk operations, and deepening the standardized construction of emergency rescue, the group has achieved a 100% rectification rate of hidden dangers, a 100% rate of employees working with certificates, and a 100% compliance rate of emergency response capabilities. By implementing precise measures, it has built a solid defense line for work safety and laid a solid foundation for high-quality development throughout the year.

Implement responsibilities and tighten the safety production responsibility chain

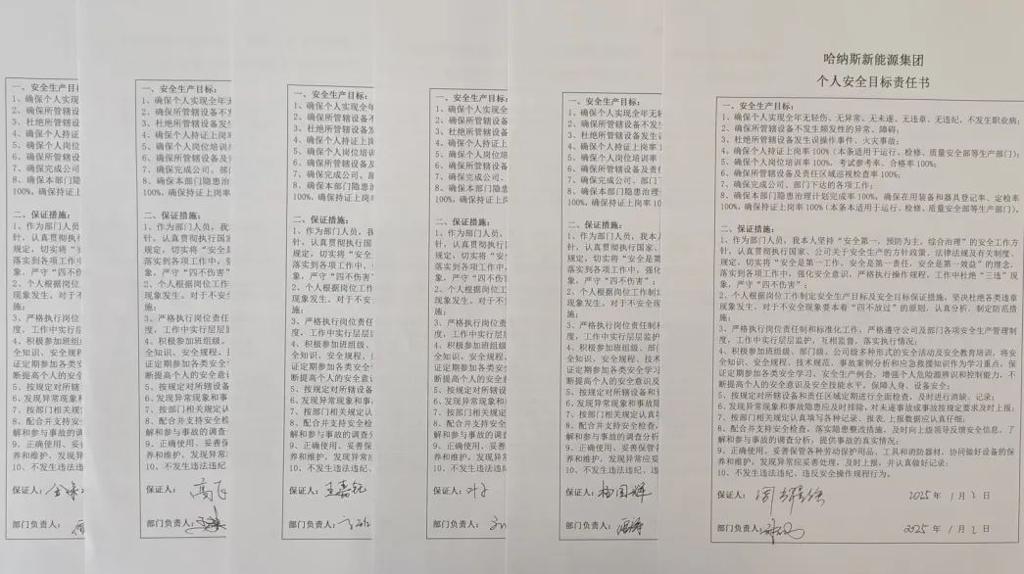

At the beginning of 2025, in accordance with the requirements of the work safety responsibility system, the New Energy Group organized various departments to sign the "2025 Annual Work Safety Target Responsibility Letter" one by one, and arranged for all employees to sign the "Work Safety Responsibility Commitment Letter" one by one, achieving the step-by-step decomposition and full coverage of safety responsibility objectives to the personnel at all positions. At the same time, the Group compiled and issued the annual safety work plan matrix, which covers special plans such as emergency drills, safety supervision and inspection, spot checks on the quality of wind turbine maintenance, etc., forming an implementation path of "one list for one position, one key focus for one month", and promoting the efficient operation of the safety management system.

Empower through Training and Tighten the String of Work Safety Mentality

Efforts are made to build a three-dimensional work safety training system with "internal and external coordination". Externally, relying on professional institutions, special training for qualification certifications such as special operations and high-altitude operations is widely carried out. In the first quarter, the initial training and review of qualifications for core positions were completed for more than ten person-times, achieving the dual goals of a 100% certificate holding rate and a 100% passing rate for obtaining certificates among special operation personnel. Internally, the Quality and Safety Department takes the lead in implementing the "Safety Classroom Entering Stations" action. A total of 13 sessions of special rotation training have been carried out, focusing on content such as laws and regulations, special operation procedures, and potential hazard investigation techniques. A total of 947 person-times participated in the training, with a coverage rate of 100%. A "retrospective of accident cases" learning mechanism has been established, and the "Collection of Typical Industry Accident Cases" has been compiled. Through scenario-restoration teaching, the risk prediction ability of all employees is strengthened.

Investigation and Governance: Secure the Pass of Work Safety Risks

Strictly implement the three-level penetrating inspection mechanism of the company, department and station yard. Conduct systematic diagnosis from multiple dimensions such as the compliance of the system, the operating status of equipment, the effectiveness of fire-fighting facilities, and the integrity of infrastructure. As of now, in 2025, a total of 264 potential hazards have been investigated, and the rectification and closure rate has remained at 100%. Strengthen the double recheck mechanism for the maintenance quality of wind turbines. Conduct spot checks on the maintenance quality of wind turbines at a ratio of 10%. A total of 28 wind turbines have been inspected, and 65 problems have been found. Strictly implement the closed-loop management of "whoever inspects will follow up" to ensure that risks are dynamically eliminated.

Key Management and Control: Strictly Adhere to the Key Points of Safe Operation

For high-risk operations such as the replacement of major components of wind turbines, a "three strictness" review and pre-control mechanism has been established: strictly review the feasibility of the construction plan, strictly review the compliance of the qualifications of external operators, and strictly review the effectiveness of equipment detection. At the same time, the "dual guardianship" system for hoisting operations is implemented. The professional guardianship of the operators and the full-process on-site supervision by the full-time safety officers of the Quality and Safety Department are carried out jointly to ensure that the entire process of high-risk operations is under control. In the first quarter, 13 high-risk operations such as the replacement of major components were completed, with a safety execution rate of 100%.

Emergency Training: Enhance the Capability to Respond to Emergencies

Since establishing an enterprise-association collaborative training mechanism with the Ningxia Red Cross Society in 2023, the New Energy Group has continuously carried out standardized training such as cardiopulmonary resuscitation (CPR) and trauma first aid. In March 2025, a special training was jointly carried out again for newly recruited employees. Through the "theory + practical operation" mode, skills such as cardiopulmonary resuscitation and trauma first aid were mainly strengthened. A total of 22 person-times obtained relevant certificates. After the training, all on-site staff were able to work with certificates, achieving a 100% rate, and the emergency rescue capabilities of all employees fully met the standards, thus building a double-layer guarantee for work safety.

Up to now, the New Energy Group has achieved 5,126 days of safe production. It has accumulated rich and replicable practical experience in the fields of building a safety management system with full staff participation, whole-process control, and all-round coverage, as well as in aspects such as the standardization of safety management, the closed-loop management of potential hazard control, and the practicality of emergency response capabilities. With the in-depth promotion of the spring safety campaign, the phased achievements are gradually being transformed into a normalized management mechanism. Looking to the future, Hanas New Energy Group will continue to strengthen its safety foundation and provide a solid guarantee for the high-quality development of the enterprise.